With a cutting-edge R&D center and tight partnerships with prestigious clients, Metal Art Corp places a high priority on innovation.

Thorough testing, which includes outside simulations and dynamometers, guarantees flawless brake and clutch quality. Dedicated test rigs provide thorough evaluations and confirm to industry requirements.

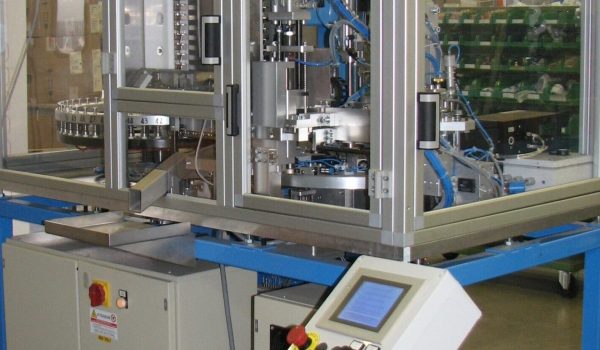

Our extensive testing procedures include evaluations of wear rate, responsiveness with various oil grades, clutch performance under varying oil temperatures, and coefficient of friction. Our evaluation capabilities are improved by advanced test rigs such as centrifugal clutch testing rigs, SAE II test rigs, brake dynamicometers, and chase testing apparatus.

In addition to bench testing, our R&D team has the appropriate vehicles to assess the performance and durability of our goods prior to the initiation of mass production. Additionally, we conduct frequent testing during mass production to guarantee product consistency.

Single clutch plate dynamometer

Complete clutch assembly dynamometer

Complete brake shoe & brake pad dynamometer